lime slurry pump factories

Latest articles

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreSlurry Pump

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreIt is important that the pump you choose has components that will not wear out from abrasive slurries.

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreSelecting And Operating A Slurry Pump

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreReduced inventory

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreSlurry Pump

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreSubmersible Slurry Pump

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read More>Slurry Pump

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreTypically, slurries are.

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read MoreSlurry Pump

lime slurry pump factories...

lime slurry pump factories 【lime slurry pump factories】

Read More

Popular articles

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- Monitoring

- >Slurry Pump vs Mud Pump

- A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

- From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

Latest articles

-

There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

-

There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

-

Slurry Pump

-

- Keeping clean catch basins clean from solids

-

The company uses advanced computer assistant engineering software to design products and technology, which makes our

Links

- In conclusion, the wheels in sliding doors are more than just a simple accessory; they are the unsung heroes that make the seemingly effortless movement possible. Their importance lies not just in their function but also in their ability to enhance the user experience. As technology continues to advance, we can expect even more sophisticated wheel systems that will further refine the operation of sliding doors, ensuring a perfect blend of aesthetics, functionality, and convenience.

- In conclusion, replacing the wheels on a sliding screen door is a manageable DIY task that requires patience and attention to detail. Regular maintenance and prompt replacements when needed can significantly enhance the performance and longevity of your screen door. Remember, prevention is always better than cure, so keep an eye on your door's condition and address any issues promptly.

Aluminum is a highly recyclable and environmentally friendly material. The use of aluminum profiles for windows and doors contributes to sustainable development because this aluminum is a high quality material that can be recycled over and over again without losing its properties.

III. The choice of aluminum profile considerations- Wrought iron, derived from the Old English word writhan, meaning to work, signifies the extensive handcraftsmanship involved in its production. Its strength and malleability make it ideal for crafting intricate designs, gates, railings, and even furniture pieces. However, finding a reliable supplier that can cater to your specific needs can be a daunting task.

1. Top-Mounted Rollers These rollers are attached to the top of the window sash. They are less visible and allow for a clean appearance. Top-mounted rollers are often used in heavy-duty applications where added support is needed.

Sliding doors are a popular choice for modern homes, offering a seamless transition between indoor and outdoor spaces. However, over time, these doors may become difficult to open or close, often due to misalignment caused by worn or poorly adjusted rollers. Knowing how to adjust the rollers on sliding doors is essential for maintaining their functionality and extending their lifespan. In this article, we will explore the steps involved in adjusting the rollers, the tools you’ll need, and some common issues to watch for.

- Corner Guards

The process of manufacturing aluminium window profiles involves several steps, from raw material selection to final product testing. Here is an overview of the typical process:

For starters, things can serve a practical purpose in our lives. From the moment we wake up in the morning, we interact with a multitude of things that help us navigate through our day. We use utensils to eat our breakfast, a toothbrush to clean our teeth, and a car to commute to work. Without these things, our daily routines would be much more difficult and inefficient.

With pickets spaced about 4 inches apart along the fence panel, welds affix each one to both the top and bottom railings, keeping everything sturdy and completing the unit. A standard panel usually contains about 20 pickets apiece for an overall length of 8 feet. The full height of a finished iron safety fence panel mostly tops out at 5 feet, though 4-foot panels aren’t uncommon either. Local building codes tend to dictate the height required, so your experience may vary. Finally, at either end of a fence panel is a post.

One of the main benefits of sliding cabinet rollers is their ability to maximize storage space. By utilizing the full depth of the cabinet and allowing easy access to items in the back, these rollers make it possible to store more items in a smaller space. This is especially useful in kitchens, where pots, pans, and other bulky items can take up a lot of space. With sliding cabinet rollers, every inch of space can be efficiently utilized, making it easier to keep the kitchen organized and clutter-free.

One of the key benefits of using aluminium for window frames is its strength-to-weight ratio. Aluminium is significantly lighter than traditional materials like steel, yet it maintains exceptional strength, allowing for larger glazing areas. This characteristic enables architects and builders to design windows that maximize natural light while providing a contemporary look. Additionally, aluminium profiles can be produced in a variety of shapes, sizes, and finishes, giving homeowners and builders ample options to fit different architectural styles.

Today's artisans and blacksmiths continue the tradition of crafting rod iron scrolls with a passion for detail and artistry. Custom designs are increasingly sought after, allowing individuals to incorporate personal touches or reflect specific themes in their spaces. Whether it’s a unique pattern that tells a story or a design that resonates with cultural heritage, personalized rod iron scrolls can make a profound statement.

metal gate latch.

Why Is Aluminum So Expensive?

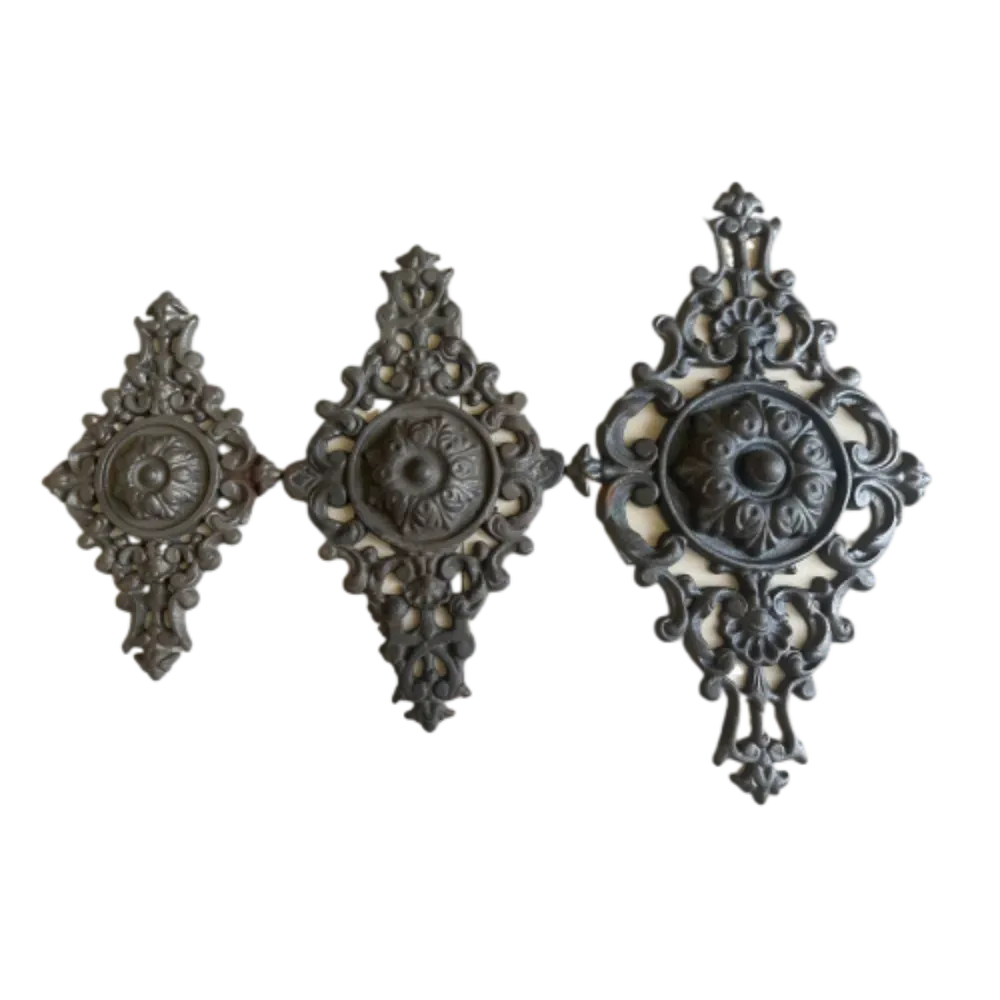

Cast Iron Railing Panel

The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens

The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens cosulet sau bulb cu baza.

cosulet sau bulb cu baza. Every aspect of the player's body must work in harmony to achieve maximum efficiency and accuracy Every aspect of the player's body must work in harmony to achieve maximum efficiency and accuracy

Every aspect of the player's body must work in harmony to achieve maximum efficiency and accuracy Every aspect of the player's body must work in harmony to achieve maximum efficiency and accuracy cast basket.

cast basket.